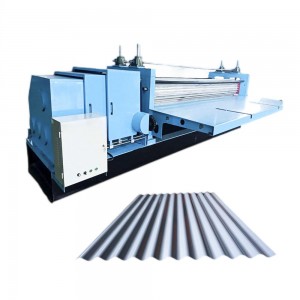

Trapezoidal Single Panel Roll Forming Machine – Product Details

Brand: Hebei Xinnuo

Category: Metal Roll Forming Equipment

This machine is a professional metal forming solution engineered for high-precision production of trapezoidal sheets, widely applied in roofing, wall panel and floor deck fabrication for industrial and civil construction projects.

It is compatible with multiple raw materials including galvanized steel, aluminum alloy and color-coated steel coils, with a material thickness range of 0.3-1.2mm and customizable coil width to meet diverse production needs. The machine features 12-18 forming stations equipped with CNC-machined, heat-treated alloy steel rollers, ensuring uniform pressure distribution and consistent trapezoid profiles without deformation. Its forming speed reaches 10-15m/min and can be adjusted flexibly via PLC control system, while the hydraulic cutting system achieves cutting accuracy within ±0.5mm, delivering burr-free finished products that meet strict international construction standards.

The machine adopts an intelligent PLC programmable control with a user-friendly touch screen interface, supporting one-key parameter setting and automatic adjustment of forming speed and cutting intervals. This design simplifies operation, reduces labor intensity by 30% and enables 24-hour continuous production with a low noise level below 75dB, ideal for large-scale manufacturing scenarios.

Constructed with a heavy-duty welded steel frame, the machine undergoes shot blasting and anti-rust coating treatment, ensuring a service life of over 10 years. Key components including bearings and gears are made of wear-resistant materials, minimizing downtime and cutting long-term maintenance costs significantly. It also offers flexible customization options: roll spacing and cutting length can be adjusted to produce trapezoidal panels of different sizes, and optional auxiliary devices such as decoiler, leveling machine and automatic stacking system are available to support full production line integration.

In terms of application scope, the finished trapezoidal panels produced by this machine are widely used in warehouses, workshops, prefabricated buildings, steel structure projects, villas and residential complexes. It caters to the needs of metal building material manufacturers, steel structure enterprises, construction companies and panel processing factories across the globe.

Hebei Xinnuo provides comprehensive after-sales support to global customers, including free on-site installation, debugging and operator training within 7 days. The whole machine comes with a 12-month warranty and lifetime maintenance service. Original spare parts are supplied at factory price with fast delivery within 3-7 days for urgent orders, and 24/7 online technical consultation is available to solve equipment operation and troubleshooting problems in a timely manner.

As a professional manufacturer with over 10 years of experience in metal forming equipment, Hebei Xinnuo adheres to strict quality control standards, with products complying with CE and ISO 9001 certifications. Our machines have been exported to more than 50 countries and regions, winning trust from global customers with cost-effective solutions, reliable quality and customer-centric service.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.