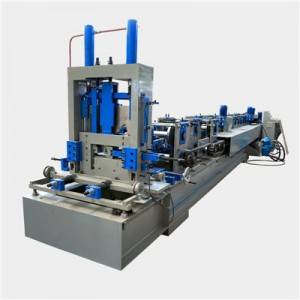

manual sheet metal curving machine tile manufacturing plant tile making machinery

Technical Parameters (depending on specific requirements of users)

| Suitable steel plate | Type | Color steel plate |

| thickness | 0.3-0.8mm | |

| Feeding width | As users needs | |

| Processing Pression | Within 1.00mm | |

| Production speed | 20-30m/min | |

| Roller stand | 5 rows | |

| Diameter | 70mm | |

| Main power | 3kw | |

| Pump power | 4kw | |

| Side panel of machine | 14mm | |

| Roller material | Carbon Steel 45# | |

| Blade material | Cr12, quenched | |

| Control system | Delta PLC control | |

| Voltage | 380V 50Hz 3phases(changeable as needs) | |

| Main structure of the machine | 300mm H-Beam | |

1. Hebei Xinnuo Roll Forming Machine located in ” The Town of Casting Molds”, enjoys convenient transportations, Di Kou Zhang Village, Nancang Road, Botou City, Hebei Province, China.

2. We are a manufacture of roll forming machine, all of the parts we made ourselves, so, we can insure the quality of our products.

3. Hebei Xinnuo Roll Forming Machine is a company integrating production, processing, sale, trade, so we will give our customers the best price.

Terms of Payment: 30% of the total contract value paid by T/T as down payment, the rest 70% of the total contract value to be paid by T/T after inspection by buyer in seller’s factory while before delivery.

Delivery: 30 days after receipt of advance payment

Service: we send technician to your country to fix the machine.The buyer should bear all the cost including: visa, Roundtrip tickets and suitable accommodation, also buyer should pay salary 80USD/day.

Warranty: 12 months limited warranty

During warranty: parts are free but buyer pay for the shipping fee

1.How to play order:

Inquiry—confirm the profile drawings and price—-confirm the PI—arrange the deposit or L/C—then OK

2:How to visit our company:

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5

hours),then we can pick up you.

3:When we exported the machines:

We have beening making and exporting the machines since from the year of 1998.

4: If you want to get more pictures or videos of the machine,please contact me now!

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

-

Bottom beam of shutter door roll forming machine

-

corrugated panel roll forming machine

-

CZ purlin roll forming machine

-

double layer panel roll forming machine

-

C21 type tile press Roof panel roll forming mac...

-

shutter door roll forming machine

-

c purlin machine manual roof tile making machin...

-

automatic stacker

-

bending machine