# Heavy-Duty Metal Coil Slitting Line | Precision Slitting Solution for Steel/Aluminum Coils

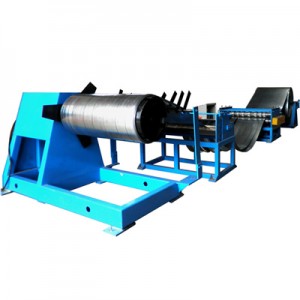

The **[Your Brand] Metal Coil Slitting Line** is a high-performance industrial machine engineered for precise slitting of various metal coils, including carbon steel, stainless steel, galvanized steel, and aluminum. Designed to meet the rigorous demands of metal processing factories, this slitting line delivers exceptional accuracy, efficiency, and durability, making it an ideal choice for coil cutting, rewinding, and processing applications.

## Core Features

1. **High Precision Cutting**

Equipped with a CNC-controlled system and high-hardness tungsten carbide blades, the slitting line ensures a cutting accuracy of ±0.1mm, delivering uniform strip widths for consistent product quality. The adjustable blade gap design supports custom slitting requirements from narrow to wide strips.

4. **Intelligent & User-Friendly Control**

The touchscreen PLC control panel allows easy setting of slitting parameters (strip width, speed, tension). Real-time operation monitoring and fault diagnosis functions minimize downtime, while the safety interlock system ensures operator protection during high-speed runs.

5. **Customizable Configurations**

Tailored to your specific needs, the slitting line offers optional upgrades such as automatic coil loading/unloading systems, edge trimming devices, and anti-scratch surface protection. We support OEM/ODM services to match your factory’s production layout and processing requirements.

## Wide Applications

Ideal for metal processing plants, steel service centers, and automotive/construction material manufacturers, this slitting line processes:

- Carbon steel, stainless steel, galvanized steel coils

- Aluminum, copper, and other non-ferrous metal coils

- Thin to heavy-gauge coils for roofing, paneling, pipe making, and more

## Why Choose Our Slitting Line?

**CE Certified** – Complies with international safety and quality standards for global markets

**Factory Direct Price** – No middlemen, cost-effective solutions for bulk orders

**One-Stop Service** – Includes installation, training, and after-sales support

**Energy-Saving Design** – Low power consumption reduces operational costs

[Your Brand] – Your Trusted Partner for Metal Coil Processing Equipment

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.