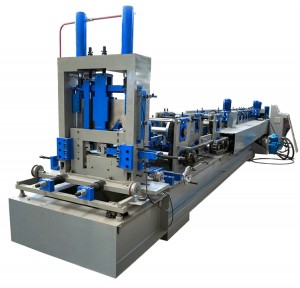

Hebei Xinnuo CZ Purlin Roll Forming Machine – Detailed Specification

Core Advantages

1. Dual-Type Quick Switch

One-click conversion between C and Z purlin forming without mold replacement, reducing downtime by over 80% and adapting to 80-300mm width range profiles for flexible production.

2. High-Precision Forming

Core rollers are quenched to HRC 58-62 hardness, with CNC machining ensuring ±0.5mm dimensional accuracy. Hydraulic cutting system delivers burr-free, flat edges, eliminating secondary processing.

Structural Features

1. Stable & Durable Frame

Integrally welded manganese steel frame with annealing treatment to eliminate internal stress, resisting deformation under long-term heavy-load operation.

2. Fully Automated Workflow

Equipped with automatic feeding, guiding, forming, cutting and collecting system, reducing manual labor by 60% and boosting production efficiency significantly.

3. Comprehensive Safety Protection

Includes emergency stop button, protective covers, overload protection and voltage stabilization device to ensure operator safety and equipment stability.

Application Scenarios

Ideal for steel structure workshops, warehouse shelving, prefabricated buildings, container houses and solar support systems, widely used in construction, logistics and new energy industries.

After-Sales Service

- 1-year warranty for the whole machine, lifelong maintenance for core components

- Free on-site installation, debugging and operation training

- 24/7 technical support, spare parts supply at factory price permanently

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.