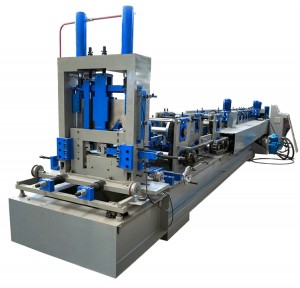

This CZ Purlin Roll Forming Machine is a high-performance metal forming core equipment for mass producing CZ steel purlins, the key load-bearing components of steel structure buildings. Adopting advanced PLC touch screen control system and fully automatic production process, it realizes seamless interchangeable forming of C and Z type purlins without mold replacement, which greatly improves production efficiency by 30% compared with traditional equipment and reduces manual labor costs effectively.

Constructed with high-strength welded steel frame and precision machined hard chrome forming rollers, the machine ensures stable operation, low noise and ultra-high forming accuracy. The finished CZ purlins have uniform dimensions, smooth surface and strong load-bearing capacity, fully complying with international building material quality standards. It supports customization of all specifications (thickness 1.5-3.0mm, adjustable width and length) according to customer drawings and project requirements, and is widely applicable to industrial workshops, logistics warehouses, prefabricated houses, commercial buildings and various steel structure construction projects.

Equipped with integrated automatic feeding, leveling, forming, hydraulic cutting and collecting devices, the whole production line realizes one-stop operation from raw steel coil to finished purlin—simple to operate and easy to maintain. All key components are selected from well-known international brands, with energy-saving motor and optimized transmission structure, featuring low energy consumption, long service life and reliable heavy-duty working performance. No frequent maintenance is required, which greatly saves subsequent operation costs for customers.

As a professional manufacturer of metal forming equipment, we provide comprehensive after-sales service including free on-site installation and commissioning, professional operator training, long-term supply of original spare parts and lifelong technical support. Our CZ purlin forming machine has been exported to Europe, America, Southeast Asia, the Middle East and more than 50 countries and regions, winning high recognition and repeat orders from global customers with superior quality and thoughtful service. OEM/ODM customization is also available to meet your personalized production needs.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.