【Product Overview】

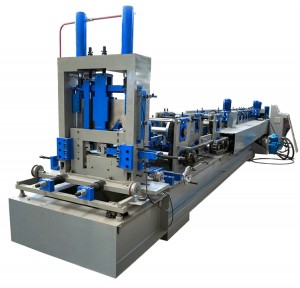

Our CZ Purlin Roll Forming Machine is a high-end metal forming core equipment independently developed for steel structure building industry, dedicated to efficient, high-precision production of CZ steel purlins—the key load-bearing structural components for various construction projects. The machine integrates PLC intelligent control, seamless C/Z interchange without mold replacement, and full-automatic one-stop production, breaking the efficiency limit of traditional purlin processing equipment. It is manufactured with heavy-duty structural design and precision machining technology, ensuring stable operation, low energy consumption and long service life. The finished CZ purlins meet international building material standards, with uniform dimensions, smooth surface and strong load-bearing capacity, making it the first choice for steel structure processing enterprises, construction engineering companies and prefabricated house manufacturers worldwide.

【Core Advantages】

1. Seamless C/Z Interchange & High Efficiency

Realize mold-free quick switching between C and Z type purlin forming, no need to disassemble and replace molds, saving 80% of mold changing time and improving production efficiency by 30% compared with ordinary equipment. Equipped with high-power energy-saving motor and optimized transmission structure, the forming speed can reach 10-25m/min, meeting mass production needs.

2. PLC Intelligent Control & High Precision

Adopt PLC touch screen integrated control system with humanized operation interface, real-time display of production parameters (speed, length, quantity), support preset production tasks and automatic counting. Precision machined hard chrome forming rollers (18-22 groups) and high-precision hydraulic cutting system ensure the dimensional error of finished purlins is ≤±0.5mm, meeting high-standard construction requirements.

3. Heavy-Duty Structure & Stable Performance

The frame is made of high-strength thick steel plate through integral welding and stress relief treatment, with strong anti-deformation and vibration resistance. All key components (bearings, motors, hydraulic parts) are selected from well-known international brands, ensuring stable and continuous operation under 24-hour heavy-duty working conditions, low failure rate and long service life (≥10 years).

4. Customizable Specifications & Strong Adaptability

Support full-customization of purlin specifications according to customer drawings and project needs: thickness 1.5-3.0mm, width 80-300mm, length customizable (unlimited). The machine is suitable for processing cold-rolled steel coil, galvanized steel coil, aluminum-zinc alloy steel coil and other raw materials, widely adapted to various construction scenarios.

5. Full-Automatic Production & Labor Saving

Integrated with automatic feeding, leveling, forming, hydraulic cutting, and finished product collecting devices, the whole production line only needs 1-2 operators to complete the operation, greatly reducing labor costs. The equipment is equipped with multiple safety protection devices (emergency stop, overload protection, light curtain protection) to ensure production safety.

【Applicable Scenarios】

The CZ steel purlins produced by this machine are widely used in various steel structure construction projects, including:

Industrial workshops, logistics warehouses, steel structure factories

Prefabricated houses, mobile container houses, temporary buildings

Commercial buildings, shopping malls, office buildings, high-rise steel structure buildings

Steel structure canopies, stadiums, exhibition halls and large-span buildings

Bridge auxiliary structures, power transmission tower accessories

【Technical Parameters】

Item Specification

Raw Material Cold-rolled steel coil, galvanized steel coil, aluminum-zinc steel coil

Material Thickness 1.5-3.0mm

Forming Width 80-300mm (C/Z interchangeable, customizable)

Forming Speed 10-25m/min (adjustable)

Control System PLC touch screen control (Siemens/Mitsubishi optional)

Forming Rollers 18-22 groups, hard chrome plated, precision machined

Cutting System Hydraulic cutting, high-speed steel blade

Power 15-30KW (according to specifications)

Voltage 380V/50Hz/3Ph (customizable for 220V/440V)

Frame Material 10-16mm thick high-strength steel plate, integral welding

Operation Fully automatic (1-2 operators)

Overall Dimension Customizable (according to specifications)

Weight 5-12T (according to specifications)

【Processing Flow】

Raw Steel Coil → Automatic Feeding → Material Leveling → Precision Roll Forming → Hydraulic Fixed-Length Cutting → Finished Product Collecting → Packaging and Storage

One-stop fully automatic processing, no manual intermediate operation, high production efficiency and consistent product quality.

【Our Services】

1. Pre-Sales Service

Professional technical team provides free project design and equipment matching scheme according to customer’s production needs and site conditions;

Free sample processing and test run for customers, video live broadcast of test run process;

Provide detailed product parameters, quotation list and after-sales service commitment.

2. In-Sales Service

Real-time feedback of production progress, provide production photos/videos regularly;

Professional packaging (seaworthy wooden case) to ensure safe transportation;

Arrange professional logistics and shipping, provide one-stop door-to-door delivery service.

3. After-Sales Service

Free on-site installation and commissioning by professional engineers, on-site training of operators (including operation, maintenance, troubleshooting);

Provide detailed operation manual and maintenance manual (Chinese/English);

Long-term supply of original spare parts at factory price, no middleman difference;

Lifelong free technical support: 24-hour online after-sales team, timely solve equipment problems by phone/WeChat/Video;

Engineers can be dispatched to the site for maintenance at the customer’s request (only charging round-trip transportation and accommodation fees).

【About Us】

We are a professional manufacturer of metal forming equipment with many years of R&D, production and sales experience, specializing in the production of CZ purlin roll forming machines, roof tile roll forming machines, floor deck roll forming machines and other steel structure processing equipment. Our factory has a complete R&D team, advanced production equipment (CNC machine tool, laser cutting machine) and strict quality inspection system, all products pass ISO9001 quality system certification and CE certification.

Our products have been exported to more than 80 countries and regions including Europe, America, Southeast Asia, the Middle East, Africa and Australia, winning high recognition and trust from global customers with superior quality, reasonable price and thoughtful after-sales service. We adhere to the concept of “customer first, quality-oriented, innovation-driven”, and are committed to providing customers with high-quality metal forming equipment and one-stop steel structure processing solutions.

【FAQ】

Q1: Can the machine be customized according to our specific requirements?

A1: Yes, we support full OEM/ODM customization, including purlin specifications, control system brand, voltage, overall dimension and other parameters, to meet your personalized production needs.

Q2: How long is the delivery time?

A2: The standard model delivery time is 15-20 working days, the customized model delivery time is 25-35 working days, depending on the customization content.

Q3: Do you provide spare parts?

A3: Yes, we provide a full set of free wearing parts with the machine, and supply all original spare parts at factory price for a long time, with fast delivery.

Q4: How to install and commission the machine?

A4: Our professional engineers will go to your site for free installation and commissioning, and conduct on-site training for your operators until they can operate the machine proficiently.

Q5: What is the warranty period of the machine?

A5: We provide 12 months free warranty for the whole machine (excluding wearing parts), and lifelong free technical support. During the warranty period, we will replace the damaged parts for free if there is any quality problem caused by non-human factors.

【Call to Action】

Looking for a high-efficiency, high-precision CZ Purlin Roll Forming Machine for your steel structure production? We are your reliable partner! Contact us now to get the latest quotation, free project design and sample test run service! We will reply to your inquiry within 24 hours and provide you with the most professional solutions.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.