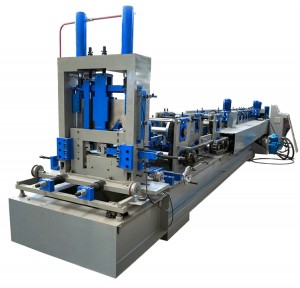

Automatic CZ Purlin Roll Forming Machine – Technical & Commercial Details

As a key equipment in steel structure manufacturing, our automatic CZ purlin roll forming machine is engineered to produce high-quality C/Z section purlins with high efficiency, flexibility and reliability. It combines advanced cold roll forming technology with intelligent control, making it an ideal choice for medium and large-scale steel structure enterprises, building material manufacturers and construction companies worldwide.

Technical Highlights (Differentiated Advantages)

What distinguishes our CZ purlin forming machine from competitors is its integrated design and advanced core technology, which bring more value to your production:

- Integrated Punching & Forming: The punching unit is integrated with the forming host, realizing synchronous punching and forming. Compared with separate punching equipment, it saves production space, reduces material waste and improves processing precision, ensuring that the punching position is accurate and consistent with the forming profile.

- Quick Roller Adjustment System: Adopts worm gear and worm adjustment mechanism, which can adjust the roller gap and position accurately and quickly. The C/Z profile switching can be completed within 5-8 minutes without disassembling the roller set, which greatly improves the production flexibility and adapts to the mixed production of multiple specifications.

- High-Speed & Stable Transmission: Equipped with hard tooth surface reducer and frequency conversion speed regulation system, the transmission efficiency is as high as 98%, the operation is stable without noise, and the forming speed can reach up to 18m/min, which effectively improves the production capacity and meets the large-batch production needs.

- Anti-Scratch & Wear-Resistant Design: The forming rollers are coated with hard chrome after precision processing, which not only enhances wear resistance but also prevents scratches on the surface of the steel coil. The feeding and receiving parts are equipped with rubber rollers, further protecting the surface quality of finished purlins.

- Intelligent Fault Diagnosis: The PLC control system is equipped with an intelligent fault diagnosis function, which can automatically detect faults such as overload, voltage instability and equipment jamming, and display the fault reason and solution on the touch screen, reducing maintenance time and labor costs.

Key Performance Parameters

Performance Index

Value

Remarks

Applicable Material

Cold-rolled steel, galvanized steel

Yield strength: 235-355MPa

Material Thickness Range

1.2-3.5mm

Customizable up to 4.0mm

CZ Purlin Size

C60-C350mm, Z60-Z350mm

Flange width: 40-150mm

Max Forming Speed

18m/min

Stepless adjustable

Forming Stations

16-22 stations

Optimized design for stable forming

Cutting Precision

±0.5mm

Hydraulic fixed-length cutting

Total Power

18-38KW

Depends on forming speed and thickness

Machine Dimension (L×W×H)

12×1.8×2.2m

Customizable according to configuration

Weight

12-22 tons

Varies with stations and configuration

Production Process & Efficiency

The whole production process of the CZ purlin roll forming machine is fully automatic, with simple operation and high efficiency, and the specific process is as follows:

1. Steel Coil Loading: Use a crane to load the steel coil onto the hydraulic decoiler, and fix it with hydraulic expansion.

2. Decoiling & Leveling: The decoiler uncoils the steel coil stably, and the leveling device eliminates the internal stress of the steel plate to ensure flat feeding.

3. Punching: The integrated punching unit punches holes according to the set position and size, which is synchronized with the feeding speed.

4. Roll Forming: The steel plate is gradually formed into C/Z purlin through multiple groups of forming rollers, with smooth forming and no deformation.

5. Fixed-Length Cutting: The hydraulic cutting system cuts the formed purlin into the set length automatically, with smooth cut and no burrs.

6. Receiving & Stacking: The finished purlins are conveyed to the receiving table automatically, which is convenient for stacking and packaging.

With this automatic production line, one operator can complete the whole production process, and the daily output can reach 800-1500 meters (depending on the specification of purlins), which greatly improves production efficiency and reduces labor costs.

Application & Market Advantage

The CZ purlins produced by our machine are widely used in steel structure buildings, with the advantages of light weight, high strength, easy installation and good seismic performance. They are ideal supporting components for roofs and walls of workshops, warehouses, prefabricated houses, greenhouses and other projects.

Our machine has obvious market advantages:

- Cost-Effective: High production efficiency, low energy consumption and maintenance cost, which can help customers reduce overall production costs and improve market competitiveness.

- Customizable: We can customize the machine according to the customer’s specific needs, including purlin size, production speed, configuration, etc., to adapt to different market demands.

- International Standard: The machine adopts international standard components (Siemens, Delta, etc.), with stable performance and easy maintenance, and meets the electrical and safety standards of various countries.

- Global Service: We have a professional after-sales team and overseas service points, providing timely installation, commissioning and maintenance services for customers around the world.

Packaging, Shipping & After-Sales

- Packaging: The machine is wrapped with waterproof and moisture-proof plastic film, and the key components are packed in wooden boxes to prevent collision and rust during transportation.

- Shipping: We can arrange sea, air or land transportation according to the customer’s needs, and provide complete shipping documents (commercial invoice, packing list, bill of lading, certificate of origin, etc.).

- After-Sales Service: 1-year free warranty, lifelong technical support, 24-hour online service, on-site installation and training, and cost-price spare parts supply.

If you are looking for a high-quality, efficient and flexible CZ purlin roll forming machine, we are your best choice. Contact us now to get a customized solution and quotation!

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.