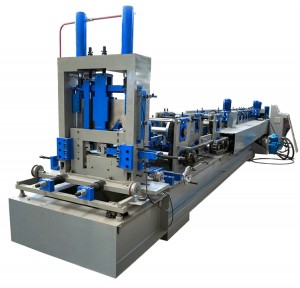

CZ Purlin Roll Forming Machine Detailed Description

1. Product Overview

The CZ Purlin Roll Forming Machine is a specialized automatic processing equipment designed for the continuous production of C-type and Z-type steel purlins, which are essential structural components in steel structure buildings. Unlike traditional manual or semi-automatic forming methods, this machine integrates feeding, leveling, roll forming, length measurement, hydraulic cutting, and stacking into one integrated production line, realizing high-efficiency, high-precision, and labor-saving purlin manufacturing. It is widely recognized as a core equipment in the steel structure processing industry, suitable for mass production of standard or customized purlins with different specifications.

2. Core Structure & Components

The machine is composed of multiple functional modules, each with precise design and reliable performance, ensuring stable operation and consistent product quality. The main components include:

- Uncoiler: Equipped with a hydraulic expansion mechanism, it can stably hold steel coils with a width of 300-1250mm and a weight of 1-5 tons. The uncoiling speed is synchronized with the forming speed to avoid material deviation or tension inconsistency, effectively protecting the surface of the steel plate from scratches.

- Leveling Device: Composed of multiple precision leveling rollers, it is used to correct the deformation of the steel coil (such as bending, warping) caused by transportation and storage. The leveling effect is adjustable, ensuring that the steel plate enters the forming unit in a flat state, which lays a foundation for high-precision forming.

- CZ Forming Unit: The core part of the machine, consisting of 12-20 groups of forming rollers made of high-quality alloy steel (after quenching and tempering treatment, hardness up to HRC58-62). The rollers are precisely processed by CNC lathes, with smooth surface and accurate size. The forming process adopts step-by-step progressive forming, which can realize quick switching between C-type and Z-type profiles by adjusting the PLC parameters and roller positions, without manual mold replacement, saving time and labor.

- PLC Control System: Adopts imported Siemens or Mitsubishi PLC controller, matched with a 7-10 inch touch screen. The operation interface is simple and intuitive, allowing operators to set parameters such as product specification, length, production quantity, and cutting speed easily. The system has automatic fault alarm, parameter memory, and production statistics functions, which is convenient for daily operation and management.

- Hydraulic Cutting System: Equipped with a high-pressure hydraulic cylinder and a sharp alloy steel cutting blade, it realizes fast and smooth cutting of formed purlins. The cutting speed is adjustable (0.5-3m/min), and the cutting surface is flat and free of burrs, avoiding secondary processing. The cutting process is synchronized with the forming process, ensuring no material waste and high production efficiency.

- Length Measuring Device: Adopts encoder automatic length measurement, with an error of ≤±1mm/m. It can accurately measure the length of the formed purlin in real time, and send a signal to the PLC system when the set length is reached, triggering the hydraulic cutting device to complete automatic cutting, ensuring the consistency of product length.

- Stacking Device: Optional automatic stacking mechanism, which can automatically stack the cut purlins in order, reducing manual handling labor intensity and avoiding damage to the purlins during stacking. The stacking height is adjustable according to user needs.

- Frame Structure: Made of thickened steel plates, welded by robot arm, with high structural strength and good stability. The frame is treated with anti-rust spraying, which can effectively resist corrosion and extend the service life of the machine.

3. Working Principle

The working process of the CZ Purlin Roll Forming Machine is fully automatic, with clear steps and high coordination, which can realize continuous and efficient production:

- Feeding & Uncoiling: The steel coil is installed on the uncoiler, and the hydraulic expansion mechanism fixes the coil to prevent slipping. The uncoiler starts to uncoil the steel plate, and the steel plate is sent to the leveling device through the guide roller.

- Leveling: The deformed steel plate is leveled by the leveling rollers, eliminating internal stress and ensuring the flatness of the plate.

- Progressive Forming: The leveled steel plate enters the CZ forming unit, and under the action of multiple groups of forming rollers, it is gradually bent and formed into C-type or Z-type profiles according to the preset shape. The forming process is smooth and uniform, without obvious indentation or deformation.

- Length Measurement & Cutting: The encoder measures the length of the formed purlin in real time. When the length reaches the set value, the PLC system sends a signal to the hydraulic cutting system, which completes the automatic cutting quickly. The cut purlin is sent to the stacking device.

- Stacking: The stacking device automatically stacks the cut purlins in order, and the operator can take them away in batches, realizing the integration of production and stacking.

4. Technical Parameters

|

Parameter Name

|

Specification

|

|---|---|

|

Raw Material

|

Galvanized steel plate, cold-rolled steel plate, color steel plate; Thickness: 0.8-3.0mm

|

|

Raw Material Width

|

300-1250mm

|

|

Product Type

|

C-type, Z-type (switchable without mold replacement)

|

|

Product Specification

|

C-type: C80-C300mm; Z-type: Z80-Z300mm (customizable)

|

|

Production Speed

|

5-15m/min (adjustable according to product specification)

|

|

Cutting Method

|

Hydraulic cutting, cutting surface flat without burrs

|

|

Length Accuracy

|

≤±1mm/m

|

|

Control System

|

PLC control + touch screen operation

|

|

Power Supply

|

380V/50Hz, 3-phase (customizable according to user’s local voltage)

|

|

Total Power

|

15-30KW (depending on machine model)

|

|

Machine Weight

|

5-12 tons (depending on machine model)

|

|

Overall Dimensions

|

8000×1500×1800mm – 12000×1800×2200mm (depending on machine model)

|

5. Product Advantages

- High Efficiency & Automation: Integrates feeding, leveling, forming, cutting, and stacking into one, realizing fully automatic continuous production. The production speed can reach 5-15m/min, which is 5-8 times that of manual processing, greatly improving production efficiency and reducing labor costs (only 1-2 operators are needed for the whole production line).

- Quick Profile Switching: Unique CZ dual-mode design, no need to replace molds when switching between C-type and Z-type profiles. It only takes 5-10 minutes to adjust parameters through the touch screen, which is flexible and convenient, suitable for small-batch and multi-specification production.

- High Forming Precision: The forming rollers are made of high-quality alloy steel, processed by CNC precision machining, and the forming process adopts step-by-step progressive forming. The product has uniform size, smooth surface, no indentation, and the length error is ≤±1mm/m, meeting the national steel structure engineering standards.

- Durable & Stable: The frame is made of thickened steel plate, welded by robot arm, with high structural strength and good stability. The key components (rollers, hydraulic system, PLC controller) are imported or domestic well-known brands, ensuring long service life (normal service life can reach 8-10 years) and low failure rate.

- Easy Operation & Maintenance: The touch screen operation interface is simple and intuitive, with clear parameter setting and fault prompt functions, which is easy to learn and operate even for inexperienced operators. The machine is designed with a maintenance door and lubrication system, which is convenient for daily inspection and maintenance, reducing maintenance costs.

- Customizable Design: According to the user’s actual needs, we can customize the machine’s raw material width, product specification, production speed, and additional functions (such as automatic stacking, punching, etc.), fully meeting the personalized production needs of different users.

6. Application Scenarios

The CZ Purlin Roll Forming Machine is mainly used for the production of C-type and Z-type steel purlins, which are widely used in various steel structure buildings and related fields, including:

- Industrial and civil buildings: Steel structure workshops, warehouses, factories, exhibition halls, gymnasiums, supermarkets, etc.

- Agricultural buildings: Greenhouses, livestock houses, agricultural warehouses, etc.

- Prefabricated buildings: Prefabricated steel structure houses, temporary buildings, mobile houses, etc.

- Other fields: Bridges, workshops, steel structure supports, etc.

7. After-Sales Service

We provide comprehensive after-sales service to ensure that users can use the machine with confidence:

- Installation & Commissioning: Professional engineers will be sent to the user’s site to install and commission the machine, and train the operators until they can operate independently.

- Quality Guarantee: The machine has a 1-year quality guarantee period (excluding wearing parts). During the guarantee period, we will provide free maintenance and replacement of damaged parts (non-human damage).

- Spare Parts Supply: We have a complete spare parts warehouse, which can provide high-quality spare parts in a timely manner to avoid affecting production due to lack of spare parts.

- Technical Support: Provide 24-hour online technical support. If the machine fails, our technical team will respond quickly and provide solutions to help users solve problems in time.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.