# CZ Purlin Roll Forming Machine Full English Product Description

## Title

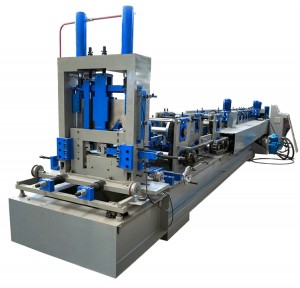

1. High Speed Automatic CZ Purlin Roll Forming Machine Steel Frame Making Machine

2. Quick Change CZ Channel Purlin Forming Machine for Steel Construction

3. Full Automatic Adjustable CZ Purlin Roll Forming Production Line with PLC Control

## Subtitle / Key Tagline

Professional manufacturer of CZ section purlin forming machinery, providing stable, high-efficiency, and long-service-life roll forming lines for steel structure buildings, warehouses, workshops, and prefabricated housing.

—

# Product Overview

Our CZ purlin roll forming machine is a highly integrated, fully automatic cold roll forming equipment specially designed for producing C-shaped and Z-shaped steel purlins. It can realize **fast size switching between C and Z profiles** without replacing rollers, greatly improving production efficiency and reducing labor cost.

This machine adopts PLC control system, hydraulic cutting, and automatic punching, which can produce various specifications of CZ purlins by simply setting parameters on the touch screen. It is widely used in steel structure factories, construction material manufacturers, and prefabricated building enterprises.

## Key Features & Advantages

- **Quick C/Z Profile Switching**

No need to change roller sets; adjust the width, height, and flange size automatically through motor adjustment, realizing fast conversion between C and Z purlins in a few minutes.

- **High Precision & Stable Forming**

The machine body adopts high-strength welded steel structure, with thickened plate and stress relief treatment, ensuring no deformation during long-term high-speed operation. The roll forming stations are scientifically designed, making the finished purlins straight, smooth, and dimensionally accurate.

- **Fully Automatic Production Line**

Equipped with PLC programmable control system and touch screen operation. The whole line includes automatic decoiling, leveling, feeding, punching, roll forming, hydraulic cutting, and automatic receiving table. One operator can manage the entire production process.

- **Customizable Specifications**

We can customize the machine according to your required purlin size range, material thickness, production speed, hole punching type, and color, to match different construction standards and market demands.

- **Durable Rollers & Long Service Life**

Rollers are made of high-quality GCr15 bearing steel, processed by precision CNC lathe and quenched treatment, with high hardness, wear resistance, and long service life. The forming surface is finely polished to ensure no scratch on the steel surface.

- **Energy-Saving & High Efficiency**

Equipped with high-power hydraulic system and variable-frequency speed control, the production speed can reach 8-15 m/min continuously. High production capacity, low energy consumption, and stable performance reduce your overall production cost.

## Main Technical Parameters

- **Model**: CZ80-300

- **Applicable Material**: Galvanized steel coil, cold rolled steel

- **Material Thickness**: 1.5-3.0 mm (customizable 1.0-4.0 mm)

- **Purlin Size Range**: C80-300mm, Z80-300mm (adjustable automatically)

- **Forming Speed**: 8-15 m/min

- **Forming Stations**: 14-20 stations (customizable)

- **Shaft Diameter**: 70mm / 80mm

- **Roller Material**: GCr15 bearing steel, quenched HRC58-62

- **Cutting Type**: Hydraulic cutting, flying cutting optional

- **Control System**: PLC + touch screen (Delta / Siemens)

- **Voltage**: 380V 3P 50Hz (customizable according to customer’s country standard)

- **Main Motor Power**: 15KW-30KW (customizable)

- **Hydraulic Station Power**: 7.5KW

- **Machine Weight**: About 12-18 tons (depends on configuration)

## Machine Structure & Components

The full automatic CZ purlin roll forming line consists of the following parts:

1. **Hydraulic Decoiler**

Automatic loading and uncoiling, suitable for 5-10 tons steel coil, with hydraulic expansion and brake system.

2. **Leveling & Feeding Device**

Level the raw material coil to eliminate internal stress, ensure flat feeding and high forming precision.

3. **Punching System**

Can be equipped with fixed or movable punching device for punching holes, slots, and connecting holes as required.

4. **Main Roll Forming Machine**

Host frame, transmission system, roll forming rollers, base, and adjustment mechanism. Sturdy structure ensures stable and continuous forming.

5. **Hydraulic Cutting System**

High-pressure hydraulic cutting, accurate length, smooth cut, no burrs. Length set on touch screen, automatic fixed-length cutting.

6. **PLC Electrical Control Cabinet**

Man-machine touch interface, parameter setting, length setting, speed adjustment, fault alarm, production counting, automatic/manual mode.

7. **Run-out Table / Receiving Table**

Automatically output finished purlins, convenient for stacking and packing.

## Application Scope

This CZ purlin forming machine is mainly used to produce **C and Z section steel purlins**, which are widely used in:

- Steel structure workshops & factories

- Large-scale warehouses & logistics centers

- High-rise steel structure buildings

- Prefabricated houses & modular buildings

- Agricultural greenhouses & breeding plants

- Stadiums, exhibition halls, and other large-span buildings

C/Z purlins are important load-bearing components in steel structure buildings, featuring light weight, high strength, easy installation, and good seismic performance.

## Why Choose Us

- 20+ years experience in roll forming machine design and manufacturing

- Customized solution according to your product drawing and capacity

- Strict quality control in material, processing, assembly, and testing

- One-year warranty, lifelong technical support and spare parts supply

- Professional after-sales team: installation, commissioning, operator training

- Exported to more than 80 countries, with high customer satisfaction

## Packaging & Transportation

- The whole machine is wrapped with waterproof plastic film and woven cloth

- Main parts are fixed with steel wire and wooden box packaging

- Suitable for sea transportation, anti-collision, moisture-proof, anti-rust

- We can arrange shipment to FOB, CIF, CNF port as your requirement

## After-Sales Service

- Provide overseas installation, commissioning and operator training

- Supply spare parts at cost price for lifetime

- 24 hours online technical support

- Remote diagnosis and maintenance via video

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.