CZ Purlin Roll Forming Machine English Product Details (New Version)

Product Introduction

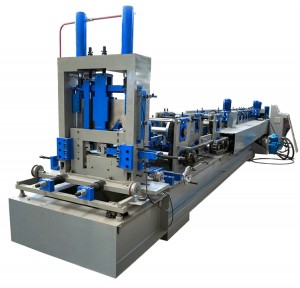

CZ purlin roll forming machine is a specialized cold roll forming equipment designed for the continuous production of C-shaped and Z-shaped steel purlins—core components widely used in steel structure construction. Unlike traditional forming equipment, this machine integrates feeding, leveling, punching, forming, cutting and collecting into one seamless process, which significantly reduces manual intervention and improves production efficiency and product consistency.

It is specially developed for processing various steel coils (galvanized steel, cold-rolled steel, colored steel, etc.) into high-precision C/Z purlins of different specifications, meeting the diverse needs of workshops, warehouses, prefabricated houses, greenhouses and other construction projects.

Core Advantages

- Easy Operation & Intelligent Control: Adopts imported PLC control system and human-machine touch screen interface, which is simple and intuitive to operate. All parameters (purlin size, forming speed, cutting length, punching position, etc.) can be set with one click, and the machine can realize fully automatic operation, suitable for operators with little experience.

- Flexible & Adjustable Specification: The unique roller adjustment structure allows quick switching between C and Z profiles without replacing the roller set, which saves time and labor costs. The purlin width, height and flange size can be continuously adjusted within the designed range, eliminating the need for multiple sets of equipment to produce different specifications of products.

- High Forming Quality & Precision: The frame is made of high-strength steel plate through integral welding and stress relief treatment, which ensures the stability of the machine during long-term high-speed operation and avoids deformation. The forming rollers are processed by precision CNC lathe and high-temperature quenching, with high hardness and smooth surface, ensuring that the finished purlins are straight, smooth, free of scratches and dimensional deviation.

- Energy-Saving & Durable: Equipped with variable frequency speed regulation motor, which can adjust the production speed according to actual needs, effectively saving energy consumption. The key components (rollers, bearings, hydraulic parts) are all made of high-quality materials, with strong wear resistance and long service life, reducing maintenance costs and downtime.

- Safe & Reliable: Equipped with multiple safety protection devices (emergency stop button, protective cover, overload protection, etc.), which can effectively avoid accidents caused by misoperation or equipment failure, ensuring the safety of operators and equipment.

Technical Specifications

Item

Specification

Applicable Material

Galvanized steel coil, cold-rolled steel, colored steel coil

Material Thickness

1.0-4.0mm (customizable according to requirements)

Purlin Specification

C type: 80-300mm; Z type: 80-300mm (adjustable)

Forming Speed

5-18m/min (stepless adjustable by frequency converter)

Forming Stations

12-22 stations (determined by product specification)

Roller Material

GCr15 bearing steel, quenched HRC58-62

Cutting Method

Hydraulic fixed-length cutting / flying cutting (optional)

Control System

PLC + touch screen (Delta / Siemens, optional)

Power Supply

380V 3Phase 50Hz (customizable for different countries)

Total Power

12-35KW (depends on configuration)

Machine Weight

10-20 tons (varies with specification)

Machine Configuration

The standard configuration of the CZ purlin roll forming machine includes the following parts, and we can also provide customized configuration according to your specific needs:

1. Hydraulic Decoiler: With hydraulic expansion and brake function, suitable for steel coils of 3-10 tons, ensuring stable uncoiling without deviation.

2. Leveling Device: Equipped with multiple groups of leveling rollers, which can effectively eliminate the internal stress of the steel coil, make the feeding flat, and improve the forming precision.

3. Punching Unit: Optional fixed or movable punching device, which can punch round holes, square holes, long holes, etc., to meet the installation needs of purlins.

4. Main Forming Machine: The core part of the equipment, including frame, transmission system, forming rollers and adjustment mechanism, ensuring stable and continuous forming.

5. Cutting System: Hydraulic cutting with high pressure, fast cutting speed, smooth cut and no burrs, realizing fixed-length cutting according to the set parameters.

6. Electrical Control Cabinet: Integrates PLC, frequency converter, contactor and other electrical components, with stable performance and convenient maintenance.

7. Receiving Table: Automatically collects the finished purlins, which is convenient for stacking and packaging, reducing manual handling.

Application Scenarios

The CZ purlins produced by this machine are widely used in various steel structure projects, mainly including:

- Industrial workshops, factories and warehouses

- Prefabricated houses, modular buildings and temporary buildings

- Agricultural greenhouses, breeding sheds and solar greenhouses

- Large-span buildings such as stadiums, exhibition halls and shopping malls

- Roof and wall support components of steel structure buildings

Quality Assurance & After-Sales Service

We adhere to the principle of “quality first, customer first”, and strictly control every link from raw material purchase, processing and assembly to product testing. All machines are tested for 72 hours continuously before leaving the factory to ensure that they can work stably.

After-sales service commitment:

- One-year free warranty period, during which we provide free maintenance and replacement of damaged parts (excluding wearing parts).

- Lifelong technical support: 24-hour online professional technical team, providing remote diagnosis, maintenance guidance and parameter adjustment services.

- Overseas service: Provide on-site installation, commissioning and operator training services according to customer needs.

- Spare parts supply: Provide original spare parts at cost price for life, ensuring timely supply.

Customization Service

We understand that different customers have different needs for product specifications, production capacity and application scenarios. Therefore, we provide comprehensive customized services, including:

- Customization of purlin size range and material thickness

- Configuration customization (such as adding flying cutting, automatic stacking, etc.)

- Power supply and voltage customization according to the customer’s country

- Customization of machine color and logo

Please provide your specific requirements, and our professional engineering team will design a suitable solution for you.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.