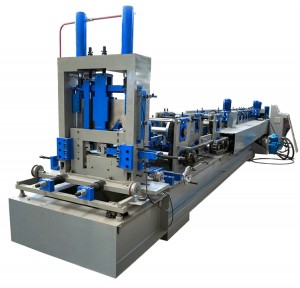

CZ Purlin Forming Machine Product Description

The CZ Purlin Forming Machine is a high-efficiency, automatic forming equipment specially designed for producing C-shaped and Z-shaped steel purlins, which are widely used as core load-bearing components in steel structure buildings such as workshops, warehouses, steel sheds, and stadiums. With advanced forming technology, stable performance and easy operation, this machine integrates uncoiling, leveling, punching, forming, cutting and other functions into one, realizing continuous and automatic production, greatly improving production efficiency, reducing labor costs and ensuring the consistency of product quality.

This CZ purlin forming machine adopts a high-quality steel frame structure, which is processed by precision welding and aging treatment, ensuring strong rigidity, stable operation and long service life. The forming roller group is made of high-quality alloy steel,经过 precision turning, quenching and tempering, and chrome plating, which has excellent wear resistance and pressure resistance, can effectively avoid scratches on the surface of the purlin, and ensure the smoothness and beauty of the product. The transmission system adopts a frequency conversion speed regulation motor and a high-precision reducer, with stable transmission, low noise and stepless speed regulation, which can be flexibly adjusted according to the production needs and material characteristics.

One of the outstanding advantages of this machine is its dual-function integration of C-shaped and Z-shaped purlin forming. By simply adjusting the position of the forming rollers and replacing the corresponding molds, it can quickly switch between C-type and Z-type production without disassembling the entire equipment, which saves time and effort and improves the utilization rate of the equipment. The product specification range is wide, and the thickness of the processed plate is 1.5mm-4.0mm, the width of the plate is 100mm-300mm, and the height of the purlin can be customized from 80mm to 300mm according to customer requirements, which can fully meet the diverse needs of different steel structure projects.

In terms of automation, the machine is equipped with a PLC control system and a touch screen operation panel, which is simple and intuitive to operate. All production parameters (such as forming speed, cutting length, punching position, etc.) can be set and adjusted on the touch screen, and the equipment can realize automatic operation after parameter setting, reducing the dependence on professional operators. The punching device adopts a precision positioning mechanism, which can accurately punch holes at the specified position according to the design requirements, with high punching precision and neat hole edges, avoiding the trouble of secondary processing. The cutting device adopts a hydraulic or mechanical cutting method, which has fast cutting speed, smooth cutting surface and no burr, ensuring the dimensional accuracy of the product.

The CZ Purlin Forming Machine pays great attention to safety performance in the design process. It is equipped with multiple safety protection devices, such as emergency stop buttons, protective covers, and photoelectric protection sensors, which can effectively prevent safety accidents caused by misoperation and ensure the personal safety of operators. At the same time, the machine has a compact structure, small floor area, convenient installation and maintenance, and the key components are standardized and universal, which is convenient for later maintenance and replacement of parts.

This machine is suitable for processing cold-rolled steel plates, galvanized steel plates and other metal materials, and the produced CZ purlins have the advantages of high strength, good toughness, beautiful appearance and easy installation. It is widely used in the construction industry, such as industrial workshops, agricultural greenhouses, commercial buildings, bridges and other steel structure projects, and is an essential key equipment for modern steel structure processing enterprises. We can also provide customized services according to the specific needs of customers, including the customization of product specifications, the addition of special functions and the optimization of the production line, to help customers improve production efficiency and market competitiveness.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.