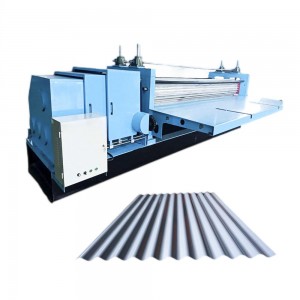

Different Details of Arc Single Board Forming Machine

Version 1 (Professional & Concise, for Alibaba/Amazon)

As a professional automatic equipment specialized in arc single board forming, our product is dedicated to offering efficient and precise solutions for plate bending processes across diverse industries. Unlike traditional forming equipment, it integrates intelligent control, high-efficiency forming and multi-scenario adaptability, enabling the rapid conversion of flat plates into high-quality arc single boards with stable performance, thereby helping enterprises boost production efficiency, refine product quality and strengthen market competitiveness.

Version 2 (Marketing-Oriented, for Independent Station/Overseas Promotion)

Specializing in automatic arc single board forming, our professional processing equipment is designed to deliver efficient, precise solutions for plate bending applications in various industrial fields. Distinguished from outdated traditional forming machines, it combines intelligent operation, high-speed forming and wide-scenario compatibility, which can quickly turn flat sheets into high-quality arc single boards with consistent performance—helping your enterprise improve production efficiency, optimize product quality and gain an edge in the global market.

Version 3 (Heavy Industry Professional Style, for Product Brochure/Exhibition)

Our product is a professional automatic processing equipment tailored for arc single board forming, committed to providing efficient and precise plate bending solutions for industries of all types. Different from conventional forming equipment, it integrates intelligent control system, high-efficiency forming technology and multi-scene adaptability, realizing the rapid transformation of flat plates into high-quality arc single boards with stable and reliable performance, thus assisting enterprises in enhancing production efficiency, upgrading product quality and reinforcing market competitiveness.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.