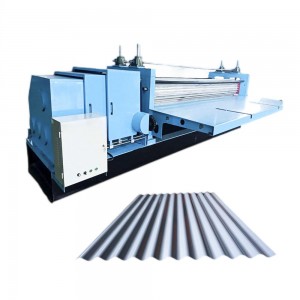

The Arc Single Board Forming Machine integrates precision machinery, digital control and efficient molding technology, representing a professional solution for high-standard curved single board manufacturing. Every core component is selected from high-quality materials and processed with strict heat treatment and precision machining, delivering excellent wear resistance, stability and service life in long-term industrial operation.

Through closed-loop positioning control and flexible pressing technology, the machine achieves high-precision forming with ultra-low tolerance, ensuring stable curvature, smooth surface and perfect appearance without defects such as waviness, delamination or deformation. The unique stress relief design eliminates rebound after forming, maintaining stable shape and size for finished products.

This equipment supports the processing of various panels and can realize single arc, hyperboloid and special-shaped forming by customizing molds. The human-machine interface is intuitive and easy to operate, with one-key parameter setting and stable automatic operation, reducing dependence on skilled workers.

It features low energy consumption, low noise and environmentally friendly production process, complying with modern industrial standards. Widely used in high-end furniture customization, architectural curtain walls, interior decoration, automotive interior and industrial engineering, the machine helps enterprises achieve high-quality, high-efficiency and automated production, creating higher product added value and brand advantages.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.