china Roll Forming Line factories - glazed tile roll foming machine metal forming machine roll former roofing machine – Xinnuo Detail:

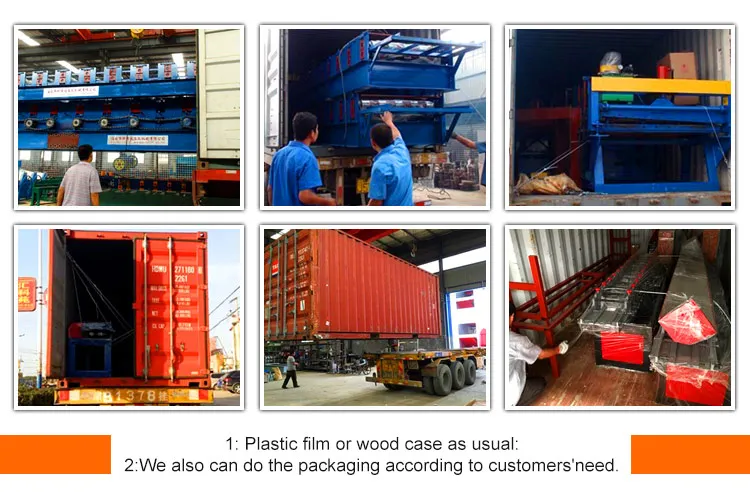

glazed tile roll foming machine metal forming machine roll former roofing machine

Equipment components:

Man-made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting

Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable.

Main parameters

| No. | main parameter of roll forming machine | |

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 1200mm |

| 3 | Rollers | 14 rows |

| 4 | Dimensions | 8.0*1.6*1.5m |

| 5 | Power | 4+3kw |

| 6 | Thickness of the plate | 0.3-0.8mm |

| 7 | Productivity | 8-12m/min |

| 8 | Diameter of the roller | Φ80mm |

| 9 | Weight | About 45.0 T |

| 10 | Voltage | 380V 50Hz 3phases |

| 11 | Rolling material | Carbon Steel 45# |

| 12 | Material of the cutting plate | Cr12 |

| 13 | Processing precision | Within 1.00mm |

| 14 | Control system | PLC control |

| All technical parameters can be changed, according to user’s need. | ||

Product detail pictures:

Related Product Guide:

We not only will try our greatest to supply outstanding services to every shopper, but also are ready to receive any suggestion offered by our buyers for china Roll Forming Line factories - glazed tile roll foming machine metal forming machine roll former roofing machine – Xinnuo, The product will supply to all over the world, such as: United States, South Africa, Qatar, Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.

-

2019 wholesale price K Former Gutter Machine -...

-

Wholesale Glazed Tile Roll Forming Machine Quot...

-

Hot-selling Roll Forming Machine Manufacturers ...

-

Factory Supply Roll Forming Machine Price - fl...

-

OEM/ODM China Cnc Cutting Machine - Hydraulic ...

-

Wholesale Roll Forming Manufacturers - Stone ...