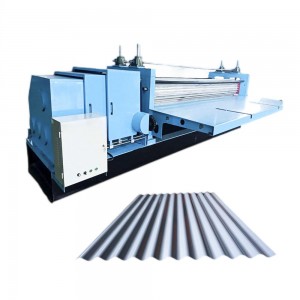

Product Description of Arc Veneer Forming Machine

The arc veneer forming machine is an automatic forming equipment specially designed for the precise deformation processing of flat plates into arc veneers. Relying on the coordinated operation of molds and compression forming mechanisms, combined with a precise positioning and adjustment system, it realizes efficient and standardized production of arc veneer forming. It completely replaces traditional manual processing or inefficient forming processes, greatly improving production efficiency and finished product consistency. It is widely applicable to the arc veneer processing needs of multiple industries and is one of the core equipment in the field of plate forming and processing.

Core Functions and Working Principle

The core of the equipment relies on the principle of plastic deformation of plates. Through the precise cooperation of the compression forming mechanism and customized arc molds, uniform pressure is applied to various flat veneers. At the same time, the precise positioning and adjustment mechanism is used to real-time control the forming radian and dimensional accuracy, avoiding the impact of forming deviation on subsequent assembly or use effect. Equipped with an independently developed CNC control system, it can flexibly set parameters such as arc radius, forming thickness, and processing speed, support one-click call of process parameter packages, adapt to the forming needs of veneers of different specifications and radians, eliminate the need for frequent mold debugging, and realize rapid switching production of multi-specification products.

To solve the stability problem during veneer forming, the equipment is equipped with multiple sets of limit rollers and pressing devices, which effectively limit the vertical and horizontal degrees of freedom of the plate, prevent the plate from deviating, wrinkling or cracking, and ensure that the inner arc of the arc veneer is smooth without wrinkles and the outer arc is flat without edge bursting. After forming, no secondary polishing and modification are required, which directly meets the requirements of subsequent processing or assembly, and greatly reduces process redundancy and material loss. Some models can be integrated with groove cutting function, which automatically completes groove processing while forming the arc of the veneer, facilitating subsequent plate splicing and fixing, eliminating the need for additional special cutting equipment and simplifying the production process.

Core Advantages of the Product

1. Precise Forming, Controllable Quality

Adopting absolute value four-axis control technology and high-precision sensors, it real-time monitors various parameters during the forming process. The forming accuracy can be controlled within ±0.1mm, ensuring that each arc veneer produced in batches has a uniform radian and consistent size, completely solving the pain points of large forming deviation and poor consistency in traditional processes. Equipped with optional mold heating or high-frequency low-temperature hot pressing functions, it can be flexibly adjusted according to the characteristics of the veneer material, improving the shaping effect of the veneer after forming, effectively avoiding rebound deformation after forming, and extending the service life of the finished product. It is especially suitable for the processing of easily deformable materials such as wood veneers and resin veneers.

2. High Efficiency, Energy Saving, Cost Reduction and Efficiency Improvement

The whole machine is driven by a frequency conversion speed regulation motor, with large transmission torque and stable speed regulation. The running speed can be flexibly adjusted according to processing needs, and the maximum processing speed can reach 8m/min. Compared with traditional manual processing, the efficiency is increased by 5-8 times, and thousands of arc veneers can be formed in a single shift, greatly improving production capacity. The optimized power transmission structure and energy-saving motor design reduce energy consumption by more than 30% compared with traditional forming equipment; no lining or a large amount of adhesive is needed during the forming process, which not only reduces material costs, but also reduces environmental pollution. At the same time, it reduces labor dependence, and 1-2 workers can complete the operation of the whole machine, greatly reducing labor costs and management costs.

3. Wide Adaptability, Flexibility and Convenience

It has a wide range of applicable materials, including solid wood veneers, density boards, particleboards, resin boards, aluminum profile veneers, color steel plates and other materials. The applicable veneer thickness range is 0.3-3.5mm (can be customized according to needs), and the arc radius can be flexibly adjusted between 50mm and 5000mm to meet different

♦ COMPANY PROFILE:

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Advantages of Roll Forming A Metal Part

There are several advantages of using roll forming for your projects:

- The roll forming process allows operations such as punching, notching, and welding to be performed in-line. Labor cost and time for secondary operations are reduced or eliminated, reducing part costs.

- Roll form tooling allows for a high degree of flexibility. A single set of roll form tools will make almost any length of the same cross-section. Multiple sets of tools for varying length parts are not required.

- It can provide better dimensional control than other competing metal forming processes.

- Repeatability is inherent in the process, allowing easier assembly of roll formed parts into your finished product, and minimizing problems due to “standard” tolerance build up.

- Roll forming is typically a higher speed process.

- Roll forming offers customers a superior surface finish. This makes roll forming an excellent option for decorative stainless steel parts or for parts requiring a finish such as anodizing or powder coating. Also, texture or pattern can be rolled into the surface during forming.

- Roll forming utilizes material more efficiently than other competing processes.

- Roll formed shapes can be developed with thinner walls than competing processes

Roll forming is a continuous process which converts sheet metal into an engineered shape using consecutive sets of mated rolls, each of which makes only incremental changes in the form. The sum of these small changes in form is a complex profile.